Horizontal Machining Centers | Horizontal CNC Mill | Boring Bar

China High Quality Parts has a wide variety of precision CNC milling centers to machine high-quality prototypes, and high-volume production of metal parts with complex geometries. Decades of proven machining experience and continuous technology investment has earned the trust of major OEMs to manufacture their mission-critical parts. Our state-of-the-art horizontal milling machines armed with multiple cutting tool storage, multi-pallet, and multi-machine cell approach - Increase machining speed, efficiency, repeatability, and productivity while ensuring the highest accuracy. We are a customer service driven machine shop with milling service that will meet or exceed your machining tolerance and quality requirements.

Machining Capabilities Summary

Part Types:

Housings, pump bodies, rotors, blocks, industrial components, and other precise shape parts

Part Size:

118” x 108” x 90”

Metal Types:

All standard metals, aluminum, armor plate, beryllium, brass, bronze, chromium, copper, gammalloy, Hastelloy, Incoloy, Inconel, Invar, manganese, molybdenum, Monel, nickel, Nitralloy, platinum, powdered metals, stainless steel, Stellite, titanium, Waspaloy, zinc, and many other superalloys

Material Types:

Castings, forgings, fabricated weldments, and billets

Milling Processes:

Boring, counterboring, countersinking, drilling, facing, pocketing, profiling, reaming, and tapping

Industries Served:

Aerospace, Defense, Food Processing, Heavy Equipment, Medical Equipment, Military, Mining, Oil & Gas, Power Generation, and Transportation

Machine Brands:

Doosan, Haas, HNK, Hyundai Wia, Kuraki, Mazak, OKK, Okuma, SNK, and Toyoda - Please refer to our Equipment List for specific mill information and capabilities.

Horizontal Milling Overview

A horizontal CNC machining center or mill has a variable speed spindle that rotates cutting tools in a horizontal orientation. The raw material is clamped directly to the index table or with the aid of a fixture. The spindle assembly and live tooling move along the travel column in a vertical direction. The index table maneuvers the workpiece in a horizontal, front to back, and rotated position against the cutting tool to achieve the precise cutting path required for removing material. We offer vast selections of surface finishes from semi-finished to fine finishing of machine parts. Like CNC turning, this is a subtractive manufacturing process.

Horizontal CNC machines allow for multiple side machining of heavier parts, extended tool life, and have cleaner gravity chip removal compared to vertical milling centers.

CNC stands for “computer numerical controlled.” Our CNC machining service converts your CAD files into G-code using sophisticated CAD/CAM software. This machining language precisely controls our CNC machines using multi-axis coordinates. This information can also create samples using 3D printing technology.

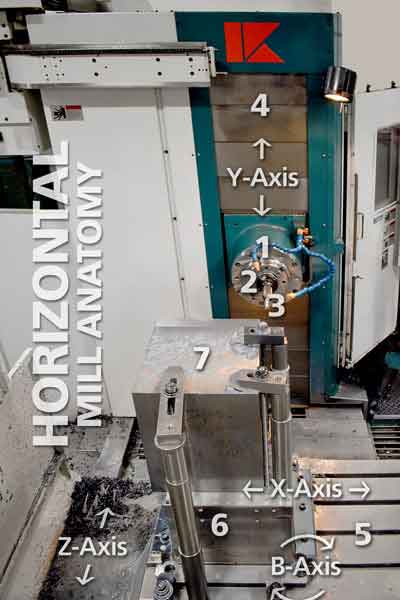

Horizontal Mill Anatomy

- Spindle Assembly - Variable speed spindle rotating in a horizontal orientation, which holds the cutting tool

- Spindle Quill - Extendable section of the spindle machining difficult areas of the workpiece due to clearance, the W-axis

- Multi-Point Cutting Tool - Removes material from the workpiece to form a part - subtractive manufacturing

- Traveling Column - The column the spindle and tooling travel vertically upon in the Y-axis

- Index Table Platform the workpiece clamps to which moves in the X-axis (perpendicular to the tool), Z-axis (parallel to the tool), and rotates on the B-axis

- Fixture - A mechanical apparatus used to position and hold the workpiece to the index table

- Workpiece - Clamps to the index table directly or with the use of a fixture

Horizontal Mill Photo Gallery

Machined Aerospace Components

Steel Fracking Block

Military Machined Components

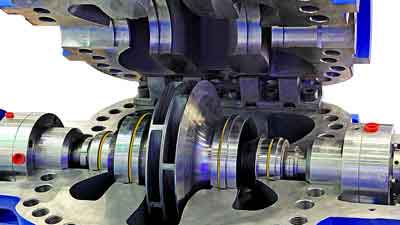

Industrial Pump Components

Industrial Engine Components

Industrial Valve Components

Machined Ship Components

CNC Milled Casting

CNC Milling Service

Other CNC machining services offered: 5-Axis Machining, Multi-Axis Machining, Horizontal Milling, Vertical Milling, Horizontal Turning, Vertical Turning, CNC Engineering, CNC Inspection, and Special Machining Process

All product names, trademarks, and registered trademarks are the property of their respective owners.