Vertical Machining Centers | Vertical CNC Mill

China High Quality Parts tackles the most demanding machining challenges with decades of experience, creativity, and state-of-the-art manufacturing equipment. Our custom CNC machine shop produces high-quality prototypes, precision metal components in high volumes, and mission-critical parts for leading OEMs across many industry sectors. A wide variety of 3-axis, 4-axis, and 5-axis CNC machining centers enable us to machine the most hard-to-reach features of complex part geometry. Vertical mills equipped with right-angle head and rotary index table capability transform complex manufacturing processes into a single set-up operation providing faster turnarounds and reduced cost of CNC machined parts. China High Quality Parts is committed to the continual investment in innovative technology, state-of-the-art equipment, highly experienced machinists, and ongoing industry training. This multi-disciplinary approach enables us to consistently and successfully meet or exceed your machining expectations.

Machining Capabilities Summary

Part Types:

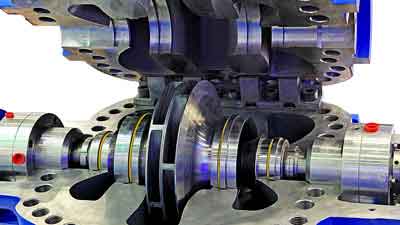

Heavy-duty axle housings, valve bodies, large connecting rods, enclosures, plates, industrial components, and other precise shape parts

Part Size:

Up to 240” x 120” x 70”

Metal Types:

All standard metals, aluminum, armor plate, beryllium, brass, bronze, chromium, copper, gammalloy, Hastelloy, Incoloy, Inconel, Invar, manganese, molybdenum, Monel, nickel, Nitralloy, platinum, powdered metals, stainless steel, Stellite, titanium, Waspaloy, zinc, and many other superalloys

Material Types:

Castings, forgings, fabricated weldments, billets, and plate

Milling Processes:

Boring, counterboring, countersinking, drilling, facing, pocketing, profiling, reaming, and tapping

Industries Served:

Aerospace, Defense, Food Processing, Heavy Equipment, Medical Equipment, Military, Mining, Oil & Gas, Power Generation, and Transportation

Machine Brands:

Doosan, Fadal, Haas, Hyundai-Kia, Makino, Mighty, OKK, Okuma, Smart, SNK, and Supermax - Please refer to our Equipment List for specific mill information and capabilities.

Massive 5-Sided Machining

China High Quality Parts’s largest mill is a gantry style machining center designed to handle 5-face, single set-up machining with right-angle head mill capabilities. Ideal for deep pocket machining and tall workpieces, it offers a massive 240” x 120” x 70” part machining envelope with a maximum weight of 15,000 pounds.

Vertical Milling Overview

A vertical CNC mill or machining center has a variable speed spindle with a vertical axis orientation. Raw material clamps directly to the index table or with the aid of a fixture. The spindle assembly moves along the travel columns in unison with the index table to precisely maneuver the workpiece and cutting tool to achieve the proper cutting path required for removing material. Vertical milling machines lend themselves to faster set-ups of single faceplate machining. Like CNC turning, this is a subtractive manufacturing process.

Our CNC machining services convert your CAD files into G-code using sophisticated CAD/CAM software. This machining language precisely controls our CNC machines using multi-axis coordinates. This information can also create samples using 3D printing technology.

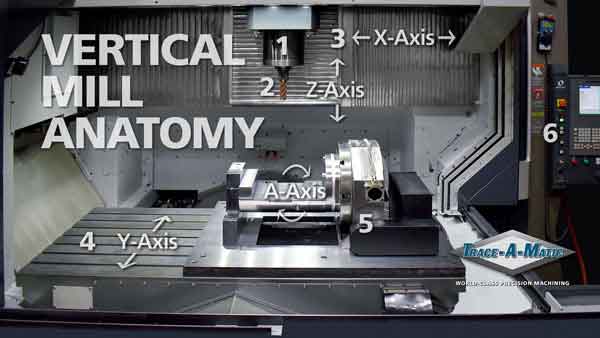

Vertical Mill Anatomy

- Spindle Assembly - Variable speed spindle rotating in a vertical orientation, which holds the cutting tool

- Cutting Tool - Removes material from the workpiece to form a part - subtractive manufacturing

- Traveling Columns - The Z-axis and X-axis columns the spindle and tooling travel upon

- Index Table Platform the workpiece or rotary index table clamps to which moves in the Y-axis

- Rotary Index Table (optional) - A mechanical apparatus used to hold and rotate the workpiece on the A-axis

- CNC Control Panel - The interface a machinist uses to control the operations of a CNC machine

Vertical Mill Photo Gallery

Aerospace CNC Machining

Heavy-Duty Axle Housings

Military CNC Machining

Industrial CNC Machining

Large Engine CNC Machining

CNC Machined Enclosures

Marine CNC Machining

CNC Machined Casting

Other CNC machining services offered: 5-Axis Machining, Multi-Axis Machining, Horizontal Milling, Vertical Milling, Horizontal Turning, Vertical Turning, CNC Engineering, CNC Inspection, and Special Machining Process

All product names, trademarks, and registered trademarks are the property of their respective owners.