Horizontal Turning Centers | Horizontal CNC Lathes

China High Quality Parts has a wide variety of precision CNC turning centers to machine high-quality prototypes, and high-volume production runs. Decades of proven machining experience and continuous technology investment has earned the trust of major OEMs to manufacture their mission-critical parts. Our state-of-the-art horizontal slant and flatbed CNC lathes armed with multiple cutting tools at the ready, and our multi-machine cell approach, increase machining speed, efficiency, and productivity while ensuring accuracy. We are a customer service driven precision machine shop, prompt to provide a free quote for our turning services.

Machining Capabilities Summary

Part Types:

Cylinders, spindles, shafts, axles, specialty pressure vessels, downhole drilling components, rollers, and other cylindrical parts

Part Size:

22” swing over carriage | 35” swing over ways (flatbed) by 160” between centers

Metal Types:

All standard metals, aluminum, armor plate, beryllium, brass, bronze, chromium, copper, gammalloy, Hastelloy, Incoloy, Inconel, Invar, manganese, molybdenum, Monel, nickel, Nitralloy, platinum, powdered metals, stainless steel, Stellite, titanium, Waspaloy, zinc, and many other superalloys

Material Types:

Large-scale castings, forgings, weldments, tubing, and bar stock

Turning Processes:

Boring, cutting, drilling, facing, internal forming, knurling, necking, parting, shoulder facing, threading (external, internal) and turning (contour, form, taper, straight)

Industries Served:

Aerospace, Defense, Food Processing, Heavy Equipment, Medical Equipment, Military, Mining, Oil & Gas, Power Generation, and Transportation

Machine Brands:

DMG Mori, Mazak, Mori Seiki, Samsung, Smart, and Weiler

Please refer to our Equipment List for specific lathe information and capabilities.

Horizontal Turning Overview

A horizontal CNC (computer numerical control) turning center or lathe rotates metal parts in a horizontal orientation during the machining process. The raw material is held in the chuck by a 3-jaw, 4-jaw, pie jaw, mandrel, collet, or face driver. The chuck connects to the headstock assembly driving workpiece rotation with a heavy-duty motor. The carriage assembly travels along the lathe bed, holding the cutting tool against the workpiece and removes material on each “side to side” pass. Like CNC milling, this is a multi-axis, subtractive manufacturing method. Longer workpieces require the use of a tailstock and steady rest to help stabilize the part while machining.

Horizontal lathes allow for longer part machining and have cleaner gravity chip removal compared to vertical turning centers. Drawbacks to horizontal CNC turning machines are they require more floor space and have part weight limitations. Turning centers equipped with live tooling (rotating tools) allow for additional boring, drilling, tapping, “turn and mill” type operations. We offer vast selections of surface finish from semi-finished to fine finishing, often not requiring a grinding process.

Contact China High Quality Parts for 3-D modeling of CAD files to finished produced parts!

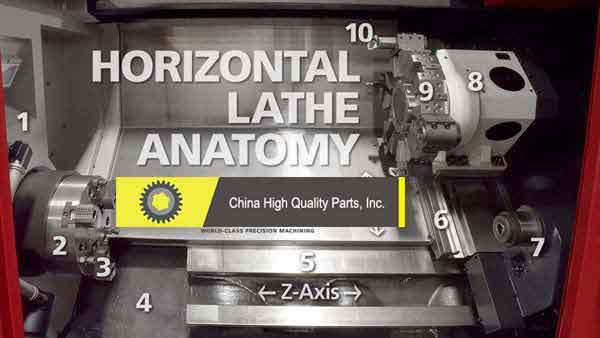

Horizontal Lathe Anatomy

- Headstock Assembly (not visible) - Drives the live spindle of the lathe

- Chuck - Positioned at the end of the spindle holding the rotating workpiece

- Jaws - Clamps the workpiece in the chuck

- Bed (slant) - The base of the lathe connected to the headstock with affixed Z-axis ways that the index drive, tooling, and tailstock travel upon

- Ways Z-Axis - The rails the index drive and tooling travel parallel to the workpiece upon

- Ways X-Axis - The rails the index drive and tooling travel perpendicular to the workpiece upon

- Tailstock - Holds the end of longer workpieces to stabilize the machining process

- Index Drive - Travels on the X-axis ways perpendicular to the workpiece holding the turret and cutting tools

- Multi-Tool Turret - Holds multiple cutting tools at the ready

- Cutting Tool - Removes material from the workpiece to form a part - subtractive manufacturing

Horizontal CNC Photo Gallery

Hub Machining

Turning Steel

Turning Aluminum

Turning Bass

Flange Machining

Aluminum Spindle

Aluminum Rollers

Brass Flanges

Rollers

Aluminum Castings

Conveyor Rollers

Forming Rollers

Housing

Hub and Rings

Machined Assembly

Large Machined Axles

Roller Guides

Steel Casings

Steel Rotors

Steel Shafts

Threaded Posts

Brass Machining

Other CNC machining services offered: 5-Axis Machining, Multi-Axis Machining, Horizontal Milling, Vertical Milling, Horizontal Turning, Vertical Turning, CNC Engineering, CNC Inspection, and Special Machining Process

All product names, trademarks, and registered trademarks are the property of their respective owners.